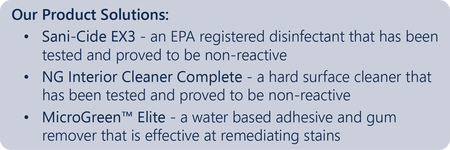

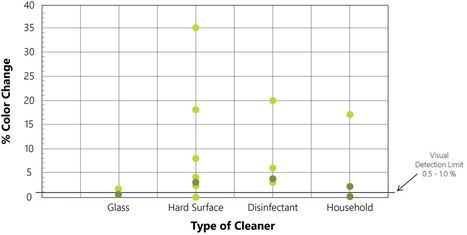

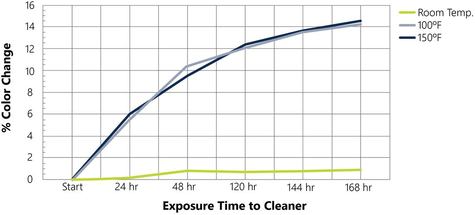

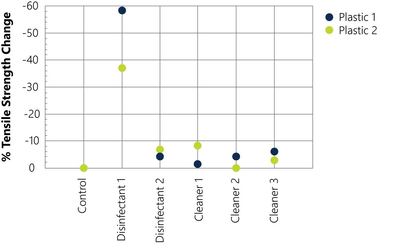

The first instance of incompatibility between cleaning chemicals and thermoplastics making up aircraft interior components was in 2012. The most obvious problem was the staining occurring on window shades and table trays. The discoloration would turn lightly colored components a dark tea color, negatively impacting the aircraft appearance and airline brand image. Cracking/crazing has occurred less frequently, but affects the functionality of components. After prolonged contact with incompatible cleaning chemicals the thermoplastic gets weaker and more brittle. This leads to cracking/crazing which causes the structural failure of tray table hinges, requiring the complete replacement of the tray tables to restore functionality.  These problems arose when new fire-retardant thermoplastics were introduced to the market. The new thermoplastics had different fire-retardant additives to meet FAR regulations; which ended up being highly reactive to the cleaning chemicals being used. Overall, the severity of the reaction depends primarily on the cleaners’ chemical formula and the fire-retardant thermoplastics’ composition. Not all fire-retardant thermoplastics are sensitive to cleaning chemicals, but some are very sensitive; it just depends on the composition of the plastic and which additives are used. As for the chemicals, it has to do with their overall formulation, some cause much more severe reactions than others. Glass cleaners tend to have little effect on the fire-retardant thermoplastics, but hard surface cleaners and disinfectants can cause more severe reactions. Disinfectants containing quaternary ammonium compounds (“quats”) tend to cause the most severe reactions. The severity of the reaction also depends on two other factors: dwell time and temperature. Typically, higher temperatures and longer dwell times lead to more severe reactions between the cleaners and the plastics. This is important to note since aircraft can experience high temperatures when sitting in the sun; a parked aircraft can easily reach 100°F (38°C) and window shades can reach 150°F (66°C). Ultimately, the longer an incompatible cleaner is used, the more likely it is that problems will occur.  To better understand what was happening, we developed a number of new experimental methods to determine the cause of the staining and cracking/crazing. This led to the development of two new, non-reactive products as well as a better understanding of the issue at hand. Both new products, NG Interior Cleaner Complete and Sani-Cide EX3, are exceptional multi-purpose hard surface cleaners and Sani-Cide EX3 has the added bonus of being an EPA registered broad-spectrum disinfectant. We also developed a simple remediation procedure using our MicroGreen Elite that would allow airlines to reverse staining that has already occurred. The Data: Types of Cleaners and Dwell Time  We used our experimental methods to test a variety of cleaners to see if they would react to fire retardant thermoplastics: 15 aviation cleaners and 6 household cleaners were used. Out of those 21 cleaners, 15 caused detectable staining on the plastics! The plot to the right shows the severity of the plastic’s discoloration when exposed to the cleaners for an extended time at elevated temperatures. The variety of products tested and found reactive showed that this was not a simple isolated issue, but a potentially wide-spread problem. Note: Anything over 1.0% color change is noticeable to the human eye (a colorimeter was used to measure the color change). Darker dots represent overlap.  The testing also showed that the longer the plastic was exposed to the reactive chemical, the more severe the reaction would be (see left plot). This means that the prolonged use of an incompatible chemical would lead to more severe staining as well as more instances of cracking/crazing. In order to preserve the appearance and functionality of aircraft interior components, it is important to use a non-reactive cleaning chemical. The Data: Tensile Strength  We also developed a procedure to test the tensile strength of various plastics before and after being contacted with different cleaning chemicals. The results show a decrease in the tensile strength with each of the products after 8 hours of dwell time; meaning the plastics got weaker and more brittle. Test pieces of plastic were left to sit in the liquid for an extended time to show the “worst case scenario” for what could happen. As seen on the right, some products are capable of causing a much greater decrease in strength than others. This decrease in strength leads to the eventual breakage of the plastic, e.g. the hinges of tray tables snapping. Using a non-reactive chemical is the most effective way to ensure the plastic will not experience a decrease in strength and remain fully functional.

2 Comments

2/21/2019 06:00:59 am

Great article on Chemical Compatibility with Thermoplastics. By following a specific approach you can go to the end of your typical yield. Tatvachintan is moreover produced cleaning synthetics

Reply

Leave a Reply. |

Archives

May 2020

Categories

All

BLOG SUBSCRIPTION

|

800.447.5775

[email protected]

RSS Feed

RSS Feed