|

The COVID-19 pandemic has been in the forefront of everyone’s mind lately, leading to uncertainty, business shutdowns, and travel restrictions. Now, with less people traveling, aircraft are being removed from service and placed into temporary storage. Without proper preparation, this could develop into significant odor problems for airlines due to malodor forming bacteria. Left unchecked, these detrimental bacteria have time to grow and multiply resulting in significant odor issues. Properly preparing aircraft now will reduce the effort required to eliminate these malodors later when returning the aircraft to service. It is important to eliminate the source of the malodor by effective cleaning and treating the bacteria and fungi that cause the malodors. Malodors can arise from several areas throughout the aircraft; from the lavatory, to the galley, to the cabin itself. In each case, the cause of the malodor is the same: odor causing bacteria, invisible to the naked eye. By attacking the source of the malodor, whether physically or by interrupting the process whereby odors are created, the problem can be solved for the longer term. Left untreated, these bacteria multiply rapidly creating a biofilm that causes the malodors. Below are Celeste’s recommendations to remove malodor sources, treat the bacteria, and prevent odors from forming during storage using products that:

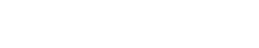

PREPARING THE AIRCRAFT INTERIOR FOR STORAGE Clean and disinfect all surfaces with Sani-Cide EX3 according to product label. Sani-Cide EX3 is an EPA registered broad-spectrum disinfectant and highly effective cleaner, which is safe to use on all aircraft interior surfaces. When using this product, treat all touch points, areas where food/drink spills may have occurred, or where bodily fluids such as sweat and urine build-up accumulate. These areas are breeding grounds for mold, mildew, and bacteria. Be sure to treat the following areas:

Deodorize with Biozyme EX3* in areas where moisture typically collects and any areas that cannot be accessed with a cleaning solution. Biozyme EX3 contains enzymes that consume odor causing bacteria, mold, and mildew that develop while the aircraft sits in storage. Simply spray onto the targeted surfaces and allow it to dry. Suggested areas for treatment are:

*Consider a monthly application of Biozyme EX3 if the aircraft is being stored in a humid climate. ** To prevent clogs and odors in lavatory and galley sink drains, it is recommended to treat them first with Liquid Scrub™ Drain Cleaner and rinse. Then apply Biozyme EX3 to coat the drain walls with odor controlling enzymes that will continue to fight malodors while the plane sits in storage. PREPARING WASTE SYSTEMS FOR STORAGE Recirculating Toilet System Soak holding tank using Sani-Tank® N to remove the source of odor causing bacteria, urine scale, and organic build-up that can be found on the toilet bowl, flapper valve, shroud area, and other waste tank components. Rinse with water. Sani-Tank® N is an excellent heavy-duty cleaner/descaler that will maintain the cleanliness of all waste tank components. Vacuum Toilet System Treat the system according to your regular weekly waste line maintenance program prior to storage. Gly-Vak® and Sani-Tank® N are specifically formulated for this purpose. Gly-Vak® uses mild organic acids with proprietary surfactants, foaming and gelling agents to completely coat waste tube walls to prevent scale from being deposited and to soften existing scale for removal. Sani-Tank® N is a companion product to Gly-Vak® that will emulsify and remove the softened scale, ensuring the lines are clean. Doing the extra work now to properly prepare aircraft for storage will save time and reduce efforts later when planes are placed back to service. Contact your Celeste Account Manager for assistance with products recommended in the storage process and best practices for bringing aircraft back into service.

1 Comment

|

Archives

May 2020

Categories

All

BLOG SUBSCRIPTION

|

800.447.5775

[email protected]

RSS Feed

RSS Feed